|

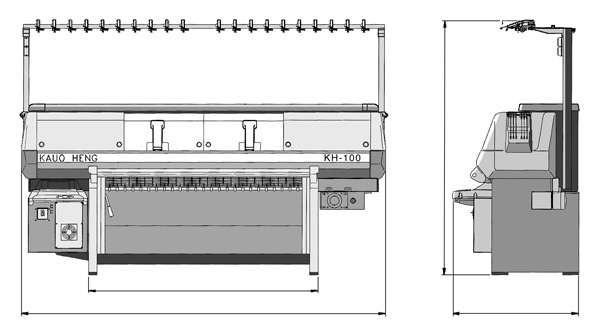

MODEL

|

KH-100

|

|

GAUGE

|

7G, 10G, 12G, 14G, 16G, 18G

|

|

KNITTING WIDTH

|

60" (152 cm) , 80" (203 cm)

|

|

CAM SYSTEM

|

Two carriages, Single system.

|

|

KNITTING SPEED

|

Max. 1.2m/sec.

Knitting speed varies according to gauge, yarn and knitting condition.

|

|

YARN CARRIERS

|

12 yarn carriers on 3 rails.

|

|

NEEDLE SELECTION

|

Full jacquard selection via special solenoids.

|

|

NEEDLE BED

|

Replaceable segment needle bed.

|

|

STITCH DENSITY

|

30 levels independent selection, electronic control with stepping motor 00-198 steps.

|

|

RACKING

|

Racked by servo motor and high precision ball screw system.

Racking also available 1/2 pitch from any position.

|

|

FABRIC TAKE DOWN

|

32 levels changeable speed, automatically adjustable on each level.

|

|

STOP MOTION

|

Yarn break, knot, press off, needle break, shock, over torque, piece count, over run, program error etc.

|

|

DRIVE

|

AC servo motor, tooth shape driving belt, no oil needed.

Variable adjustable programmable speed levels.

|

|

TOP TENSIONS

|

Electronic top tensions easy to thread the yarn through.

|

|

SAFETY COVER

|

Full safety cover for anti-noise and dust proofing.

Emergency stop buttons.

|

|

OPERATION LAMP

|

Green : normal operation.

Yellow : abnormal / manual stop.

|

|

FLUORESCENT LAMP

|

Inside of safety cover and fabric take-down.

|

|

WOODEN CASE

|

2900 x 1100 x 1790 mm. N./G. Weight 1000/1250 kgs. (60")

3480 x 1100 x 1790 mm. N./G. Weight 1150/1450 kgs. (80")

|