|

MODEL

|

KH-224

|

|

GAUGE

|

3G, 3.5G, 4G, 5G, 7G, 10G, 12G, 14G.

|

|

KNITTING WIDTH

|

90" ( 37" x 2 ) , 100" ( 42" x 2).

|

|

CAM SYSTEM

|

Two carriages, Double system. ( 2 + 2 )

Knitting system tree-way technique and transfer with split stitch function.

|

|

KNITTING SPEED

|

Max. 1.2m/sec.

Knitting speed varies according to gauge and knitting condition.

|

|

YARN CARRIERS

|

16 yarn carriers on 4 double rails.

|

|

NEEDLE SELECTION

|

Full jacquard selection via special solenoids.

|

|

TRANSFER

|

Simultaneous transfer, front or back, independent of carriage direction.

|

|

NEEDLE BED

|

Replaceable segment needle bed.

|

|

SINKER SYSTEM

|

Moveable sinker equipment.

|

|

STITCH DENSITY

|

32 levels independent selection, electronic control with stepping motor

00-230 steps on each level.

|

|

RACKING

|

Racked by servo motor and high precision ball screw system.

Racking 1/2 pitch also available from any position.

|

|

FABRIC TAKE DOWN

|

Main roller & Sub roller:

32 levels changeable speed, automatically adjustable on each level.

Sub roller with automatic opening and closing.

|

|

STOP MOTION

|

Yarn break, knot, press off, needle break, shock, over torque, piece count,

over run, program error etc.

|

|

DRIVE

|

AC servo motor, tooth shape driving belt, no oil needed.

Variably adjustable programming speed levels.

|

|

TOP TENSIONS

|

Electronic top tensions easy to thread the yarn through.

Large knots cause machine stop.

Small knots cause slow speed then automatically resume at set speed.

|

|

YARN FEED UNIT

|

Auto. positive feeding device on each left and right side.

|

|

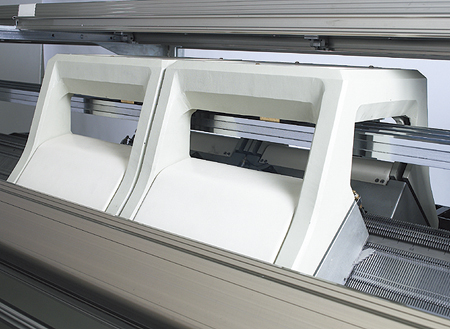

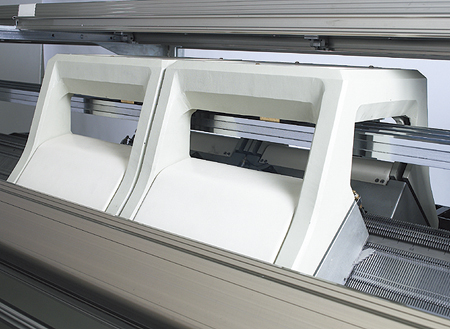

SAFETY COVER

|

Full safety cover for anti-noise and dust proofing. Emergency stop buttons.

|

|

OPERATION LAMP

|

Green : normal operation.

Yellow: abnormal / manual stop.

Red: emergency stop.

|

|

FLUORESCENT LAMP

|

Inside of safety cover and fabric take-down.

|